Business Process Improvement Consulting

A business cannot afford to remain stationary. Global competition and rapid innovation are increasing the pressure on businesses to innovate continuously, increase customer satisfaction, improve quality, and cut costs. Every business requires operational excellence.

In some instances, business leaders may be aware of areas for strategic improvement. However, in some cases, the task can be overwhelming, as business processes span multiple functions and geographies. Where do you direct your efforts toward business process improvement in order to achieve the greatest benefit with the least effort?

Business Process Management with a Focused Approach (BPM)

It is rarely justified to make an exhaustive effort to improve the efficiency and effectiveness of all business processes. Rather than that, our consulting methodology is to identify the most critical areas, those with the greatest potential for return, and those where recommendations are most likely to be implemented.

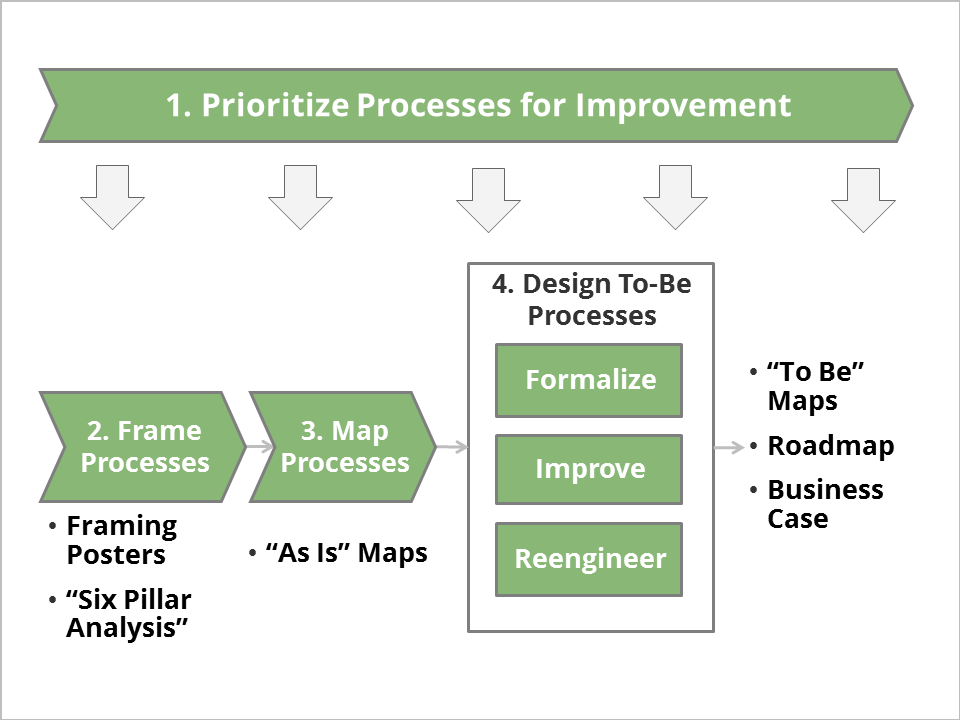

This is accomplished through a comprehensive data collection effort that identifies the business processes that are most critical to the organization’s success and also the most in need of improvement. Our business process consultants then conduct a high-level business process framing exercise for each selected process to define process boundaries, process owners and key actors, major steps, issues, and an improvement vision. Our “six-pillar analysis” considers a diverse range of process enablers, including workflow, information systems, incentives, human resources, policies, and facilities. If necessary, we also map processes in their “as-is” state, utilizing a variety of process mapping tools customized to the client’s needs.

Our consultants then design the to-be processes based on the level of improvement required. Process redesign can be classified into three broad categories:

Ensure that the process is formalized. For processes that perform satisfactorily, simply formalizing them via process modeling and process mapping, documenting roles, responsibilities, major activities, and performance criteria, and then training and coaching process actors throughout the organization on the formalized process, may suffice.

Enhance the Procedure. Substandard processes in terms of cost, schedule, or quality may require optimization, but not complete process transformation. Here, our recommendations may include the elimination of waste, the consolidation of tasks, the parallelization of activities, the automation of process elements, or the application of industry best practices. The objective is to decrease cycle time, improve quality, and optimize costs.

Process Reengineering Business processes that are beyond repair or have the potential for breakthrough performance may require radical reengineering. Here, we foster innovative thinking and the application of new technologies in order to achieve multiple-fold performance improvements.

It is also critical to consider the human aspect of change when implementing any significant change initiative. Our consultants can provide the expertise necessary to develop the change management program necessary to ensure that all process practitioners possess the awareness, desire, knowledge, and skills necessary for continuous improvement. Additionally, our change management framework establishes a process owner and process actors with defined roles, responsibilities, and process metrics for each major process.

Our Toolbox for Process Improvement

Our consultants bring a plethora of tools and methodologies for streamlining business processes that are far too numerous to list.

Our toolbox contains a variety of data collection techniques, including online surveys, interview questionnaires, and direct observation. We have a robust toolkit of analysis techniques, including process framing, value stream mapping, Ishikawa diagrams, root cause analysis, and Pareto analysis. We are particularly fond of the Theory of Constraints, with its current and future reality trees and diagramming of conflict resolution, as well as lateral thinking for problem solving and discovery of breakthrough solutions.

Our consultants also have expertise in lean manufacturing, lean six sigma, kanban, kaizen, just-in-time, total quality management, and material flow optimization for clients in the manufacturing, wholesale, and retail industries.

Not all processes require the same level of process improvement. By analyzing and prioritizing your needs and efforts, you can quickly improve profitability and gain a competitive advantage.